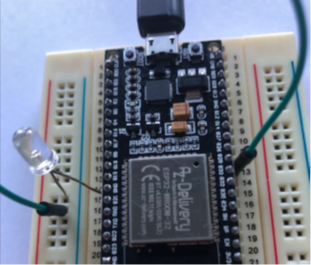

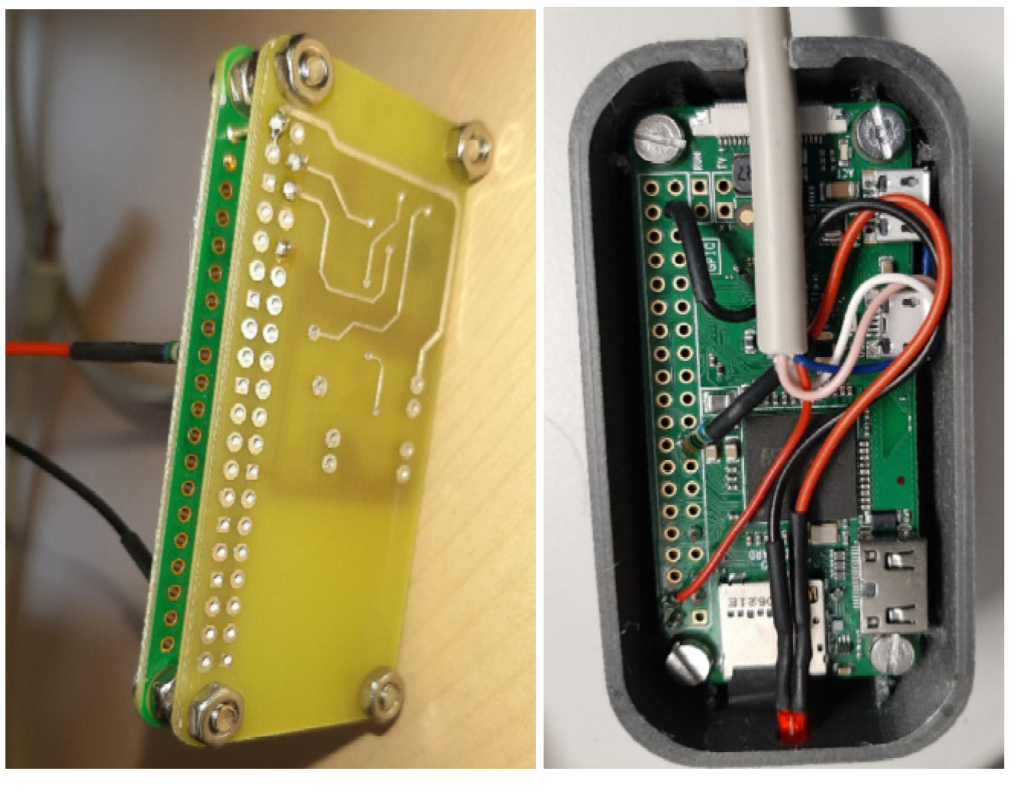

A sensor already developed by SAM for monitoring side channel pumps was adapted for operation on centrifugal pumps in the IoT.H2O project. The sensor consists of a Raspberry PI Zero and a circuit board developed at the electronics workshop of TU Kaiserslautern on which an accelerometer is mounted. The housing’s sensor was produced by 3D printing.

The operating principle of the sensor is based on a neural network. To train the neural network, operating data of the pump are recorded at different rotational speeds with a very narrow grating (speed and flow rate). The following are measured: speed, flow rate, pressures on suction and pressure side of the pump, torque and, through the pump sensor, the vibrations at the respective operating points. By training the neural network, a correlation between vibration and the pump’s operating point can be determined. After training, the operating point of the pump can be determined solely by measuring the vibration with the pump sensor. The installation of additional measurement devices (pressure transducer, MID, etc.) is no longer necessary.

This provides a very cost-effective measuring system. Data transmission from the pump sensor to the IoT node can take place via Bluetooth or the I2C interface.

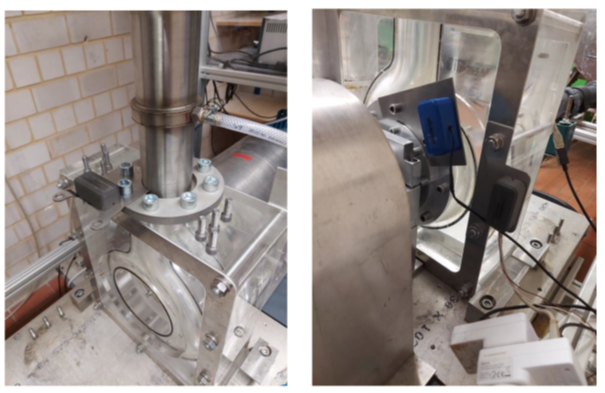

To determine the optimal sensor position, three brackets were designed for mounting the sensors on the pump. This allows multiple vibration sensors to be mounted simultaneously at different positions on the pump. One sensor is located on the pump housing, one on the flange on the motor side and one on the flange of the discharge port.